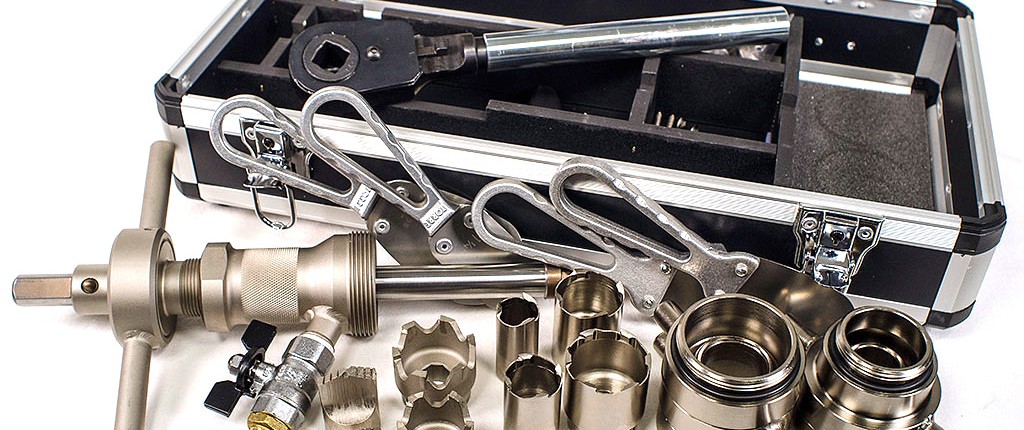

The Golf Drilling kit for use in the installation of branching saddles and connectors of 1″, 1 ¼”, 1 ½” and 2″. Contains all the necessary elements for drilling pipes of cast iron, asbestos cement, polyethylene and PVC

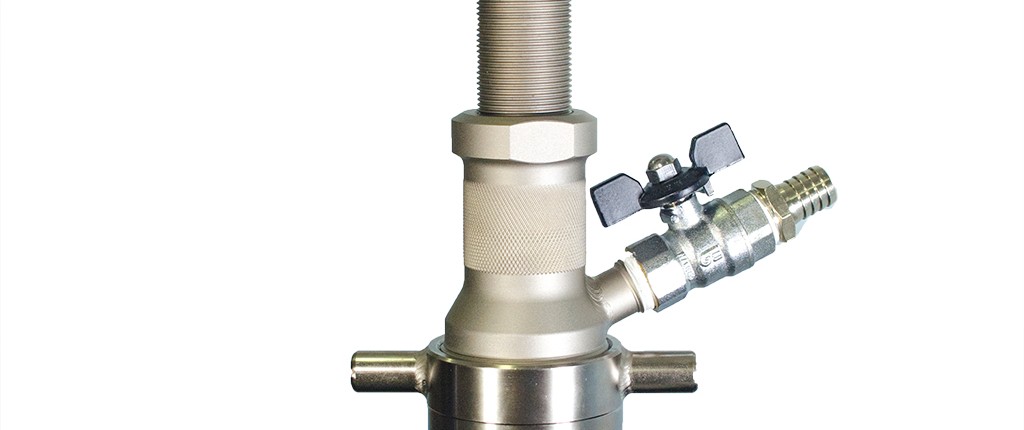

Manufactured completely in hardened steel. The compact nature of this drilling machine makes it ideal for use in areas with restricted accessibility. It comes with a drain valve for emptying shavings accumulated during drilling. This same drill, along with the Giga kit components, is used to install the 2½”, 3″ and 4″ under pressure Tees.

Applications

Golf Drilling equipment is commonly used to install service connections in sizes 1”, 1¼“, 1½” and 2”. They include all necessary components for drilling ductile iron, asbestos cement, polyethylene and PVC-O pipes.

Transport Box

The Drill Transport Box is made of PVC layered board, anodized aluminium edge protection and lock with key. The inside is divided into compartments for correct equipment storage.

Drill Materials

Drilling Machine is completely manufactured of hardened steel. The compact design of this drilling equipment makes it ideal for use in places with restricted accessibility. It comes with drain valve for emptying shavings produced along the drilling operation.

Operating Drill Equipment

The Drill equipment is designed to be operated by means of a ratchet wrench, which is supplied with the equipment, or power operated by means of electric, pneumatic or hydraulic motor.

Cutters

The Drilling MAchine is supplied with cutters and drill bits for ductile iron, asbestos cement, polyethylene and PVC-O pipes. All cutters incorporate the exclusive Torre® octogonal shaft anchoring system. Cutters for PE and PVC-O are special “zero chips” design, collecting all shaving/chips produced by the cutting operation.

Equipment Maintenance

Although these equipment does not require any special maintenance, it is advisable to clean and lubricate the drilling machine from time to time. It is also recommended to dry the equipment after each use to avoid limescale deposits, and is also advisable to carry out a check every two years in the Sarco Stopper factory.